|

ALD Headquarters:

Ha-Kharoshet Street, 30

Or-Yehuda, Israel

Tel: +972 3 7913200

Fax: +972 3 7913210

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

ALD College:

Ha-Kharoshet Street, 30

Or-Yehuda, Israel

Tel: +972 3 7913200

Fax: +972 3 7913213

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

ALD Reliability Software and Services Worldwide

| France

ALTELIOS Technology 738 rue Yves Kermen 92100 Boulogne Billancourt Tel: +33 (0) 1 70 23 95 15 Mobile: + 33(0) 7 69 99 91 94 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. Web: www.altelios.com |

India

Trident Infosol Pvt Ltd,

I Floor, 'A' Block, Kushal Garden Arcade,

II Phase, Peenya Industrial Area,

Bengaluru - 560058, India

Tel: +91 080 42878787

Fax: +91 080 42878900

|

|

| United Kingdom

RELIASS

Cams Hall, Cams Hill, Fareham, Hampshire,

PO16 8AB, United Kingdom

Tel: +44 1329 227 448

Fax: +44 1329 227 449

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Italy ISD Italia Via Val Seriana 4, 00141, Roma 00131 Rome Italy Tel: +39 06 97844838 Fax: +39 06 97844849 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. Web: www.isditalia.it |

Singapore

SHAMA Technologies (S) Pte Ltd.

BKL 67 Ayer Rajah Crescent

#03-01/02

Ayer Rajah Industrial Estate

Singapore 139950

Tel: +(65) 7764006

Fax: +(65) 7735056/+(65)7760592

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

China

Beijing Umeone Digital Tec.co., Ltd

Room 501, Block B of Huirong Mansion,

106, LianHuaChi East Rd,

Xicheng District, Beijing, 100055, China

Tel: +86 10 8205 5848

Fax: +86 10 8205 5848 609

Mobile: 15601051688

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Taiwan

SIMWEB INC. Beitun District, Taichung City 40667, Taiwan Tel: 886-4-24520859 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Portugal QTEL

Rua das Amendoeiras, 27-3º Esq.

2775-641 Carcavelos, Portugal

TM: +351 917 214 788 Tel/fax: + 351 214 570 388 ALD Scandinavia

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

South Korea

RSC, Inc. Seoul, 05248, Korea |

Sweden

LUTAB AB

Gavlegatan 22

SE - 113 30 Stockholm, Sweden

Tel: +46 (0) 8 674 1200

Fax: +46 (0) 8 674 1201

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: http://www.lutab.se

|

|

ALD Headquarters:

Ha-Kharoshet Street, 30

Or-Yehuda, Israel

Tel: +972 3 7913200

Fax: +972 3 7913210

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

ALD College:

Ha-Kharoshet Street, 30

Or-Yehuda, Israel

Tel: +972 3 7913200

Fax: +972 3 7913213

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

ALD Reliability Software and Services Worldwide

|

USA

SoHaR Incorporated

400 Corporate Pointe, Suite 300, Culver City, CA 90230

Mailing address: 5042 Wilshire Blvd #43481, Los Angeles, CA 90036 Tel: +1 (323) 410-0992 Email: This email address is being protected from spambots. You need JavaScript enabled to view it. Web: http://www.sohar.com

|

France

ALTELIOS Technology 738 rue Yves Kermen 92100 Boulogne Billancourt Tel: +33 (0) 1 70 23 95 15 Mobile: + 33(0) 7 69 99 91 94 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. Web: www.altelios.com |

|

| United Kingdom

RELIASS

Cams Hall, Cams Hill, Fareham, Hampshire,

PO16 8AB, United Kingdom

Tel: +44 1329 227 448

Fax: +44 1329 227 449

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

India

Trident Infosol Pvt Ltd,

I Floor, 'A' Block, Kushal Garden Arcade,

II Phase, Peenya Industrial Area,

Bengaluru - 560058, India

Tel: +91 080 42878787

Fax: +91 080 42878900

|

Singapore

SHAMA Technologies (S) Pte Ltd.

BKL 67 Ayer Rajah Crescent

#03-01/02

Ayer Rajah Industrial Estate

Singapore 139950

Tel: +(65) 7764006

Fax: +(65) 7735056/+(65)7760592

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

China

Beijing Umeone Digital Tec.co., Ltd

Room 501, Block B of Huirong Mansion,

106, LianHuaChi East Rd,

Xicheng District, Beijing, 100055, China

Tel: +86 10 8205 5848

Fax: +86 10 8205 5848 609

Mobile: 15601051688

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Taiwan

SIMWEB INC. Beitun District, Taichung City 40667, Taiwan Tel: 886-4-24520859 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Italy

ISD Italia Via Val Seriana 4, 00141, Roma 00131 Rome Italy Tel: +39 06 97844838 Fax: +39 06 97844849 E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. Web: www.isditalia.it Portugal

QTEL

Rua das Amendoeiras, 27-3º Esq.

2775-641 Carcavelos, Portugal

TM: +351 917 214 788 Tel/fax: + 351 214 570 388 |

Sweden

LUTAB AB

Gavlegatan 22

SE - 113 30 Stockholm, Sweden

Tel: +46 (0) 8 674 1200

Fax: +46 (0) 8 674 1201

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: http://www.lutab.se

ALD Scandinavia

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

South Korea

RSC, Inc. Seoul, 05248, Korea |

ALD is proud of the analytical capabilities, established experience, and extensive skills gained by its employees in both commercial and military projects. ALD's flexible organizational structure enables it to respond efficiently to each customers's specific needs.

Please take a look at some of ALD's brochures and videos:

|

|

|

|

| Company Profile |

In 2021 ALD has become a part of the HUB Security Group(HUB.TA). HUB Cyber Security company specializes in cyber security protecting sensitive commercial and government information.

See also:

Our customers

Our projects and solutions

ALD Reliability and Safety Software Overview

ALD Reliability, Safety and Quality Services Overview

ALD's Management Team

Contact us

ALD Software Ltd. (Advanced Logistics Development) is a world leader in Reliability Engineering, Safety and Quality Solutions.

ALD Software Ltd. has a number of subsidiaries and representations around the world.

The Company is handling hundreds of Reliability, Maintainability and Safety Projects around the world.

Company provides the following solutions:

1. Services / Consulting – a world leading professional team in the fields of Reliability, Maintainability, Safety, ILS, LCC, Quality Assurance, Risk Analysis, SIX Sigma, SPC and Thermal Design.

2. Training – ALD College established in 1984 is a prominent RAMS and Quality Engineering educator entity. Thousands of engineers were able to receive ASQ certifications as CRE, CQE, and CQM thanks to ALD college training.

3. Software Development – ALD software tools are the most advanced solutions in the market today:

a. RAM Commander – Reliability Toolkit for comprehensive RAMS analysis (Reliability, Maintainability Prediction, Spares Optimization, FMEA/FMECA, Testability, Fault Tree, Event Tree, Safety Analysis and many others.

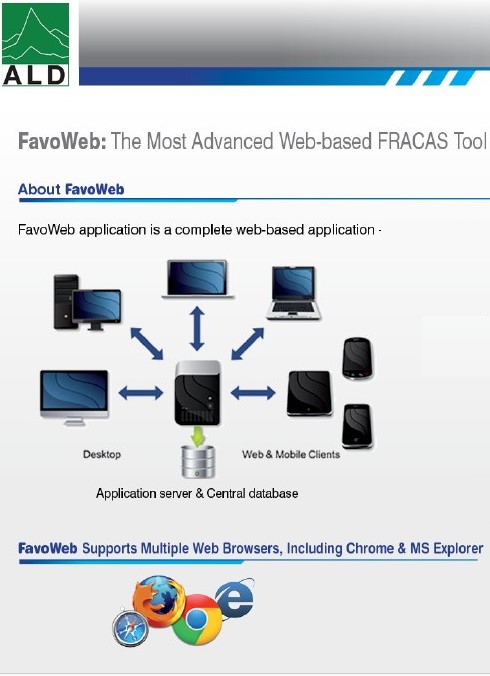

b. WEB FRACAS – User configurable application for failure analysis and corrective action

c. DLCC – a complete solution for LCC study and analysis including sensitivity analysis, spares calculation, and total ownership cost.

d. RCM – comprehensive solution for Reliability Centered Maintenance

e. FavoScope – a web based quality management system

Please take a look at ALD Software white papers and brochures:

|

|

|

| Reliability and Safety Services Catalogue | Reliability and Safety Software Tools |

ALD is part of the HUB Security Group (TASE:HUB.TA)

A merger between the ALD Group and cyber security company HUB Security has been completed.

HUB Security was established in 2017 by veterans of the 8200 and 81 elite intelligence units of the Israeli Defense Forces. The company specializes in unique Cyber Security solutions protecting sensitive commercial and government information. The company debuts an advanced encrypted computing solution aimed at preventing hostile intrusions at the hardware-level while introducing a novel set of data theft prevention solutions. HUB operates in over 30 countries and provides innovative cybersecurity computing appliances as well as a wide range of cybersecurity professional-services worldwide.

The partnership between ALD and HUB Security is a merger between a stable business infrastructure and an innovative growth engine that allows to meet all needs of ALD customer base.

See also:

Our customers

Our projects and solutions

ALD Reliability and Safety Software Overview

ALD Reliability, Safety and Quality Services Overview

Contact us