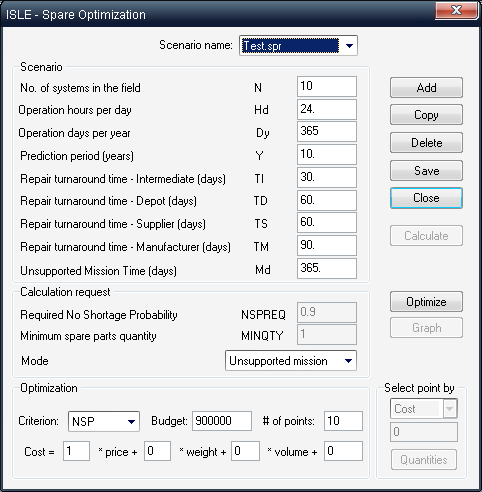

RAM Commander Spare Parts Analysis and Optimization is based on two cost optimization criteria: Total No Shortage Probability (NSP) & Availability. The module performs Cost-Availability optimization of repairable and discardable parts for all levels of repair. Spare Parts Analysis and Optimization module takes into account the variety of mission applications, e.g., when the primary restriction is weight or volume, such as for fly-away kits or when no repair or supply of spare parts is permitted (unsupported mission). Data entry for the module is minimized since the module uses data and calculations already stored in RAM Commander project.

Additional Data Required for Running the Module

•Number of systems in the field/operation

•Operation hours per day per system

•Repair turnaround time at Intermediate and Depot levels (days)

•Unsupported mission time (days) – if applicable

•Optimization criterion: NSP or Availability

•Maximal budget for spare parts

•Cost of each part

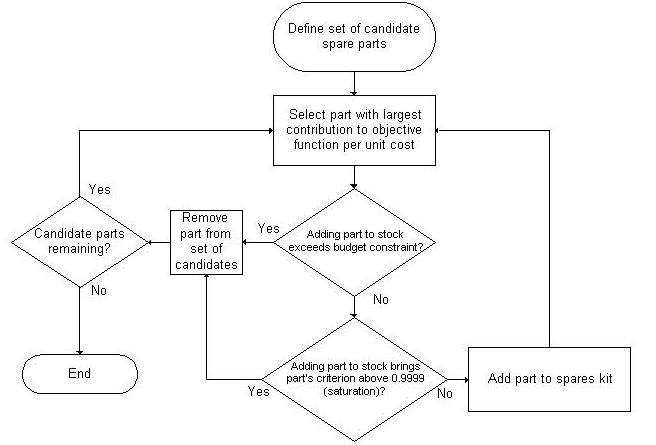

The optimization algorithm is based on convex programming as outlined in the flow chart below.

See also:

RAM Commander homepage

ALD Reliability and Safety Software Overview

Reliability&Safety Software Download

See ALD Reliability, Safety and Quality Services if you wish us to perform reliability prediction, analysis or other activities for you