When it comes to predicting the reliability of electronic components and systems, two standards frequently come up in discussions among reliability engineers: MIL-HDBK-217 and Telcordia SR-332. Both serve similar purposes but use different models, and have different advantages and limitations. This article provides a comprehensive comparison to help you determine which standard suits your specific reliability prediction needs.

What is MIL-HDBK-217?

MIL-HDBK-217, formally known as Military Handbook: Reliability Prediction of Electronic Equipment, was developed by the U.S. Department of Defense. The standard provides models for estimating failure rates of electronic components based on various environmental and operational conditions.

Key Features of MIL-HDBK-217:

- Origin: Developed for military applications in the 1960s

- Latest Version: MIL-HDBK-217F Notice 2 (published in 1995)

- Methodologies: Part Stress Analysis and Parts Count Analysis

- Component Coverage: Extensive range of electronic components

- Industry Usage: Primarily military, aerospace, and defense sectors

What is Telcordia SR-332?

Telcordia SR-332, formerly known as Bellcore, is a Reliability Prediction Procedure for Electronic Equipment originally developed for telecommunications equipment. It has since evolved to accommodate a wider range of electronic components.

Key Features of Telcordia SR-332:

- Origin: Prepared by Telcordia Network Infrastructure Solutions “NIS”, a division of Ericsson Inc.

- Latest Version: SR-332 Issue 4, March 2016

- Methodologies: Three prediction methods based on available data

- Component Coverage: Focuses on commercial-grade components

- Industry Usage: Telecommunications, networking, commercial electronics

Head-to-Head Comparison

1. Age and Relevance

- MIL-HDBK-217: Last updated in 1995. Contains outdated failure rates for modern components. Does not account for technological advances in the last 25+ years.

- Telcordia SR-332: Relatively regularly updated (latest Issue 4 - 2016). Incorporates more recent field data. Better reflects modern component manufacturing processes.

Verdict: Telcordia SR-332 has an advantage in terms of relevance for modern electronic systems.

2. Prediction Methods and Flexibility

- MIL-HDBK-217: Offers two methods: Part Stress Analysis and Parts Count Analysis. Rigid models with limited adaptability. Requires detailed component information.

- Telcordia SR-332: Provides three prediction methods:

- Method I: Black Box (no data is available from the laboratory or the field)

- Method II: Black Box Integrated with Laboratory Data

- Method III: Black Box Integrated with Field Data

More flexible approach allowing for incorporation of actual field data.

Verdict: Telcordia SR-332 offers greater flexibility by accommodating different types and sources of reliability data.

3. Accuracy of Predictions

- MIL-HDBK-217: Generally considered more conservative (pessimistic). Often overestimates failure rates. Can lead to overdesign and increased costs.

- Telcordia SR-332: More realistic predictions, especially when using Methods II and III. Better correlation with actual field performance. Accounts for burn-in period and quality processes.

Verdict: Telcordia SR-332 typically provides more realistic predictions, especially for commercial applications.

4. Industry Applicability

- MIL-HDBK-217: Strong heritage in military and aerospace applications. Recognized standard for legacy defense systems. Often contractually required in defense projects.

- Telcordia SR-332: Well-suited for telecommunications and commercial electronics. Better applicability to consumer and industrial products. More appropriate for commercial-grade components.

Verdict: Industry-dependent; MIL-HDBK-217 for military/aerospace legacy systems, Telcordia SR-332 for commercial and telecommunications equipment.

5. Environmental Factors

- MIL-HDBK-217: Extended list of various environmental conditions. Including Ground, Naval, Airborne, Space applications. Accounts for temperature, humidity, vibration, etc.

- Telcordia SR-332: Limited list of the environmental conditions. Less granular differentiation of operating environments.

Verdict: MIL-HDBK-217 provides more comprehensive environmental modeling, which can be crucial for extreme operating conditions.

6. Software Support and Implementation

- MIL-HDBK-217: Widely supported in reliability prediction software. Extensive documentation and implementation guides. Large historical user base.

- Telcordia SR-332: Increasingly supported in modern reliability tools. Clearer calculation procedures. Better documentation for implementation.

Verdict: Both standards are well-supported in reliability software tools like RAM Commander.

Example

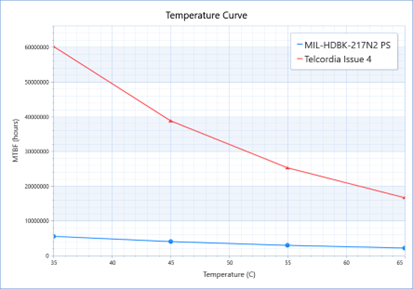

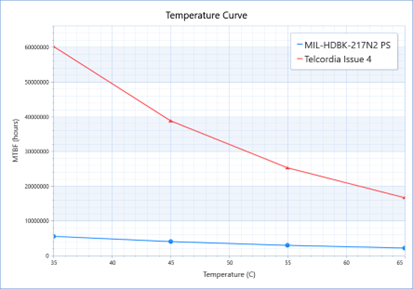

Graph of the MTBF presented below, calculated for hypothetical electrical board with components like, Integrated Circuit, Capacitor, Resistor, etc. Environment GM (Ground Mobile) and Temperature range from 35°C to 65°C.

When to Use Each Standard

Choose MIL-HDBK-217 When:

- Working on military or defense projects that specifically require it

- Dealing with legacy systems where historical comparison is important

- Operating in extreme or specialized environments (space, underwater, etc.)

- Needing conservative reliability estimates for high-risk applications

Choose Telcordia SR-332 When:

- Working with modern commercial electronics

- In telecommunications or networking industries

- Having access to field data or laboratory data

- Requiring more realistic and less conservative estimates

- Working with recently developed components

WANT TO TRY RELIABILITY CALCULATION SOFTWARE?

Industry Perspectives

According to a survey of reliability engineers:

- 68% believe Telcordia SR-332 provides more accurate predictions for commercial systems

- 72% still use MIL-HDBK-217 for defense projects due to contractual requirements

- 56% report using both standards depending on the specific application

Conclusion

The choice between MIL-HDBK-217 and Telcordia SR-332 depends on your specific application, industry requirements, data availability, and the nature of your electronic system.

For modern commercial electronics and telecommunications equipment, Telcordia SR-332 generally provides more accurate and realistic reliability predictions. Its flexibility in incorporating various data sources and requiring fewer input parameters makes it a better choice for many applications.

However, MIL-HDBK-217 still holds value for defense applications, legacy systems, and environments with extreme conditions. Despite its age, it remains a contractual requirement for many defense projects.

Many reliability engineers take advantage of both standards, applying them as appropriate for different projects or even using both as a cross-check mechanism. Reliability prediction software like RAM Commander supports both standards, allowing engineers to leverage the strengths of each.

Ultimately, the best approach may be to understand the limitations and strengths of both standards and make an informed decision based on your specific reliability prediction needs.

Further Resources

Consider using reliability prediction software that supports multiple standards to compare results and gain a more comprehensive understanding of your system’s reliability.

RAM Commander is one such comprehensive solution that supports both MIL-HDBK-217 and Telcordia SR-332, along with other reliability prediction standards.

See Also

ALD Reliability and Safety Software

ALD Reliability, Safety and Quality Services

Reliability&Safety Software Download

Other ALD Software Tools

Safety Commander - Safety Commander (RAM Commander Enterprise Collaboration Edition) is the only off-the-shelf software that provides fail-safe design for any System of System Safety Assessment (SoSSA) across multiple industries, including aerospace, railway, communication, and energy. With the ability to perform safety analysis integration on the level of aircraft or system-of-systems , Safety Commander sets itself apart as a unique solution in the market..

D-LCC – Advanced tool for life cycle cost calculation, total ownership cost and sensitivity cost analysis.