When it comes to predicting the reliability of electronic components and systems, two standards frequently come up in discussions among reliability engineers: MIL-HDBK-217 and Telcordia SR-332. Both serve similar purposes but use different models, and have different advantages and limitations. This article provides a comprehensive comparison to help you determine which standard suits your specific reliability prediction needs.

What is MIL-HDBK-217?

MIL-HDBK-217, formally known as Military Handbook: Reliability Prediction of Electronic Equipment, was developed by the U.S. Department of Defense. The standard provides models for estimating failure rates of electronic components based on various environmental and operational conditions.

Key Features of MIL-HDBK-217:

- Origin: Developed for military applications in the 1960s

- Latest Version: MIL-HDBK-217F Notice 2 (published in 1995)

- Methodologies: Part Stress Analysis and Parts Count Analysis

- Component Coverage: Extensive range of electronic components

- Industry Usage: Primarily military, aerospace, and defense sectors

What is Telcordia SR-332?

Telcordia SR-332, formerly known as Bellcore, is a Reliability Prediction Procedure for Electronic Equipment originally developed for telecommunications equipment. It has since evolved to accommodate a wider range of electronic components.

Key Features of Telcordia SR-332:

- Origin: Prepared by Telcordia Network Infrastructure Solutions “NIS”, a division of Ericsson Inc.

- Latest Version: SR-332 Issue 4, March 2016

- Methodologies: Three prediction methods based on available data

- Component Coverage: Focuses on commercial-grade components

- Industry Usage: Telecommunications, networking, commercial electronics

Head-to-Head Comparison

1. Age and Relevance

- MIL-HDBK-217: Last updated in 1995. Contains outdated failure rates for modern components. Does not account for technological advances in the last 25+ years.

- Telcordia SR-332: Relatively regularly updated (latest Issue 4 - 2016). Incorporates more recent field data. Better reflects modern component manufacturing processes.

Verdict: Telcordia SR-332 has an advantage in terms of relevance for modern electronic systems.

2. Prediction Methods and Flexibility

- MIL-HDBK-217: Offers two methods: Part Stress Analysis and Parts Count Analysis. Rigid models with limited adaptability. Requires detailed component information.

- Telcordia SR-332: Provides three prediction methods:

- Method I: Black Box (no data is available from the laboratory or the field)

- Method II: Black Box Integrated with Laboratory Data

- Method III: Black Box Integrated with Field Data

Verdict: Telcordia SR-332 offers greater flexibility by accommodating different types and sources of reliability data.

3. Accuracy of Predictions

- MIL-HDBK-217: Generally considered more conservative (pessimistic). Often overestimates failure rates. Can lead to overdesign and increased costs.

- Telcordia SR-332: More realistic predictions, especially when using Methods II and III. Better correlation with actual field performance. Accounts for burn-in period and quality processes.

Verdict: Telcordia SR-332 typically provides more realistic predictions, especially for commercial applications.

4. Industry Applicability

- MIL-HDBK-217: Strong heritage in military and aerospace applications. Recognized standard for legacy defense systems. Often contractually required in defense projects.

- Telcordia SR-332: Well-suited for telecommunications and commercial electronics. Better applicability to consumer and industrial products. More appropriate for commercial-grade components.

Verdict: Industry-dependent; MIL-HDBK-217 for military/aerospace legacy systems, Telcordia SR-332 for commercial and telecommunications equipment.

5. Environmental Factors

- MIL-HDBK-217: Extended list of various environmental conditions. Including Ground, Naval, Airborne, Space applications. Accounts for temperature, humidity, vibration, etc.

- Telcordia SR-332: Limited list of the environmental conditions. Less granular differentiation of operating environments.

Verdict: MIL-HDBK-217 provides more comprehensive environmental modeling, which can be crucial for extreme operating conditions.

6. Software Support and Implementation

- MIL-HDBK-217: Widely supported in reliability prediction software. Extensive documentation and implementation guides. Large historical user base.

- Telcordia SR-332: Increasingly supported in modern reliability tools. Clearer calculation procedures. Better documentation for implementation.

Verdict: Both standards are well-supported in reliability software tools like RAM Commander.

Example

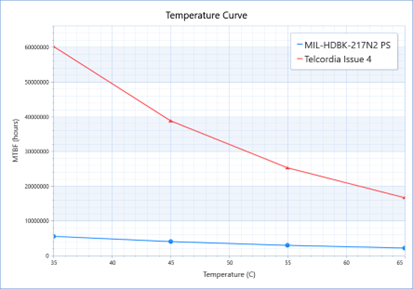

Graph of the MTBF presented below, calculated for hypothetical electrical board with components like, Integrated Circuit, Capacitor, Resistor, etc. Environment GM (Ground Mobile) and Temperature range from 35°C to 65°C.

When to Use Each Standard

Choose MIL-HDBK-217 When:

- Working on military or defense projects that specifically require it

- Dealing with legacy systems where historical comparison is important

- Operating in extreme or specialized environments (space, underwater, etc.)

- Needing conservative reliability estimates for high-risk applications

Choose Telcordia SR-332 When:

- Working with modern commercial electronics

- In telecommunications or networking industries

- Having access to field data or laboratory data

- Requiring more realistic and less conservative estimates

- Working with recently developed components

Industry Perspectives

According to a survey of reliability engineers:

- 68% believe Telcordia SR-332 provides more accurate predictions for commercial systems

- 72% still use MIL-HDBK-217 for defense projects due to contractual requirements

- 56% report using both standards depending on the specific application

Conclusion

The choice between MIL-HDBK-217 and Telcordia SR-332 depends on your specific application, industry requirements, data availability, and the nature of your electronic system.

For modern commercial electronics and telecommunications equipment, Telcordia SR-332 generally provides more accurate and realistic reliability predictions. Its flexibility in incorporating various data sources and requiring fewer input parameters makes it a better choice for many applications.

However, MIL-HDBK-217 still holds value for defense applications, legacy systems, and environments with extreme conditions. Despite its age, it remains a contractual requirement for many defense projects.

Many reliability engineers take advantage of both standards, applying them as appropriate for different projects or even using both as a cross-check mechanism. Reliability prediction software like RAM Commander supports both standards, allowing engineers to leverage the strengths of each.

Ultimately, the best approach may be to understand the limitations and strengths of both standards and make an informed decision based on your specific reliability prediction needs.

Further Resources

- MIL-HDBK-217F Notice 2

- Telcordia SR-332 Issue 4

- IEC 61709: Electric components – Reliability – Reference conditions for failure rates and stress models for conversion

- FIDES Guide 2022: Reliability Methodology for Electronic Systems

- SN 29500 2015: “… expected values of failure rates …”

Consider using reliability prediction software that supports multiple standards to compare results and gain a more comprehensive understanding of your system’s reliability. RAM Commander is one such comprehensive solution that supports both MIL-HDBK-217 and Telcordia SR-332, along with other reliability prediction standards.

See Also

ALD Reliability and Safety Software

ALD Reliability, Safety and Quality Services

Reliability&Safety Software Download

Other ALD Software Tools

Safety Commander - Safety Commander (RAM Commander Enterprise Collaboration Edition) is the only off-the-shelf software that provides fail-safe design for any System of System Safety Assessment (SoSSA) across multiple industries, including aerospace, railway, communication, and energy. With the ability to perform safety analysis integration on the level of aircraft or system-of-systems , Safety Commander sets itself apart as a unique solution in the market..

D-LCC – Advanced tool for life cycle cost calculation, total ownership cost and sensitivity cost analysis.

FavoWeb Safety Management System

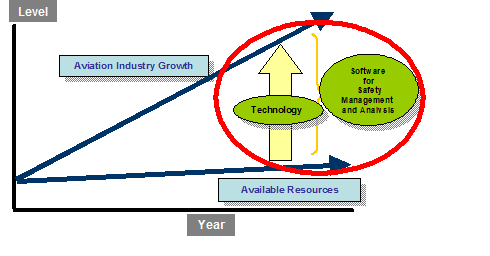

With the expected growth in air transportation, there is a need to make greater efforts and adopt new measures to continue improving aviation safety.

The use of Safety Management Systems (SMS) at airports can contribute to this effort by helping airports detect and correct safety problems before they result in aircraft accidents or incidents.

Safety Management System in Aviation Industry

Leading regulatory aviation agencies declared guidelines for the establishment of SMS at airports:

ICAO Annex 14:

ICAO Annex 14:

"A systematic approach to managing safety, including the necessary organizational structures, accountabilities, policy and procedures"

![]() FAA AC 150/5200-37:

FAA AC 150/5200-37:

"Formal business like approach to managing safety risk. It includes systematic procedures, practices and policies for the management of safety"

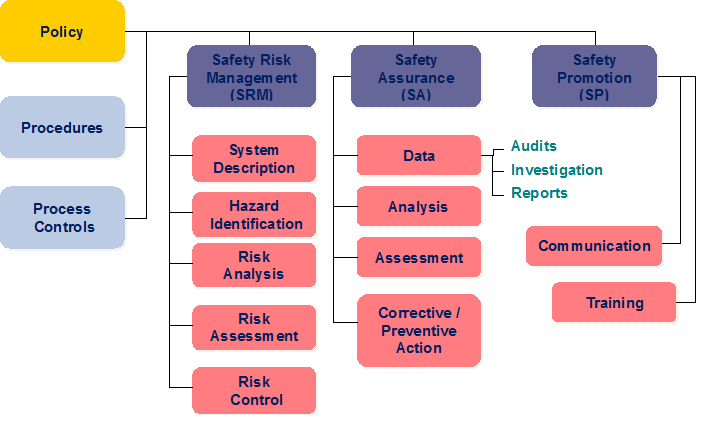

Safety Management system structure by ICAO

Main Goals of Safety Management Process

1. Identify possible hazards with significant risk of an accident, injury or damage

2. Select appropriate corrective action to eliminate this risk or to reduce it to acceptable levels

3. Monitor the corrective action undertaken and test its efficiency

An important element of each SMS is establishing a formal reporting procedure within the airline management that will enable the senior management to:

- Monitor the level of safety performance that is being achieved throughout the organization.

- Be aware of all of the possible threats or risks.

- Take appropriate corrective action to minimize those risks.

This requires the availability of operational data and means for analyzing this data.

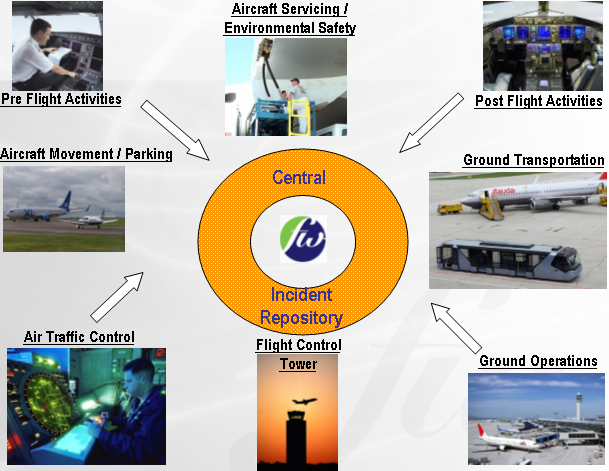

FavoWeb FRACAS software meets the 4 basic requirements provided by any Safety Management System:

Collection and Management of Operational Data

FavoWeb FRACAS functionality and configuration allow for uniform and easy data collection. Forms are flexible and allow our customer to identify fields or data to be collected and tracked. FavoWeb FRACAS is user friendly and wherever possible implements on "point-and-click" technique, so that data collection becomes easy and therefore accurate. This also facilitates analysis and reporting since "free-text" input is minimized.

Analysis of the Data

FavoWeb FRACAS offers numerous reliability and statistics trending reports combined with the flexible query mechanism.

Risk Assessment

ALD RAM Commander's Safety Assessment Software Module implements tasks of qualitative and quantitative safety assessment required during system development:

• Generation and verification of safety requirements

• Identification of all relevant failure conditions

• Consideration of all significant combinations of failures causing failure conditions

• Generation of output reports starting from the stage of Functional Hazard Analysis (FHA/PHA) and ending with the System Safety Assessment (SSA) verifying that the design meets safety requirements.

Corrective Action Effectiveness Assessment

FavoWeb FRACAS Corrective Actions (CA) module provides full support for all corrective action activities: CA definition, implementation, verification and follow-up, documentation of the entire process and measuring the efficiency of the proposed CA with the help of special metrics.

This mechanism offers 2 options:

• Existing Corrective Action Mechanism: from CA identification, FRB/MRB decision making and follow-up to CA implementation

• Modified CA mechanism tailored to the requirements

Flight Incident Report

ALD Reliability and Safety Software Overview

Reliability&Safety Analysis Software Download

ALD Reliability, Safety and Quality Services

Reliability prediction standards are essential tools for estimating the failure rates and reliability of electronic components, systems, and products. They assist engineers in designing robust systems, planning spare parts, and ensuring safety and performance. This overview covers the most widely used and relevant reliability prediction standards, all of which are supported by RAM Commander from ALD Software.

1. MIL-HDBK-217 (Military Handbook 217)

- Full Name: MIL-HDBK-217F: Reliability Prediction of Electronic Equipment

- Origin: U.S. Department of Defense

- Purpose: Provides failure rate models for electronic components based on environmental and operational conditions.

- Applications: Primarily used in military and aerospace sectors.

- Pros:

- Extensive database for military-grade components.

- Well-established and widely recognized.

- Cons:

- Last updated in 1995, making it outdated for modern components.

- Conservative failure rates that may not reflect current technology.

2. Telcordia SR-332 (Previously Bellcore)

- Full Name: Telcordia SR-332: Reliability Prediction Procedure for Electronic Equipment

- Origin: Telcordia Technologies (formerly Bellcore)

- Purpose: Provides methods for calculating failure rates and Mean Time Between Failures (MTBF) for electronic equipment.

- Applications: Widely used in telecommunications, networking, and commercial electronics.

- Pros:

- Regularly updated to include modern components.

- Flexible models for different quality levels.

- Cons:

- Primarily focused on telecommunications equipment.

3. IEC 61709

- Full Name: IEC 61709: Electrical Components - Reliability - Reference Conditions for Failure Rates and Stress Models for Conversion

- Origin: International Electrotechnical Commission (IEC)

- Purpose: Provides guidelines for calculating failure rates of electronic components using reference conditions and stress models.

- Applications: Industrial electronics, consumer electronics, and automation systems.

- Pros:

- Flexible approach allowing the use of manufacturer-specific data.

- Suitable for a wide range of electronic components.

- Cons:

- Requires detailed environmental and operational profiles.

- Requires reference failure rates.

4. FIDES Guide 2022 Edition A

- Full Name: FIDES Guide 2022 Edition A

- Origin: Developed by a consortium of European aerospace and defense companies under the supervision of the French Ministry of Defense.

- Purpose: Focuses on reliability prediction with an emphasis on manufacturing processes and supplier quality.

- Applications: Aerospace, defense, and high-reliability industrial electronics.

- Pros:

- Considers process quality and supplier reliability.

- Supports user defined Mission Profiles.

- Cons:

- Complex data requirements.

- Limited global adoption compared to MIL-HDBK-217.

5. HDBK-217Plus

- Full Name: HDBK-217Plus: Handbook of Reliability Prediction Models

- Origin: Reliability Information Analysis Center (RIAC)

- Purpose: An independent, modernized standard that provides reliability prediction models for electronic components, with a focus on updating failure rates to reflect the latest technological advances.

- Applications: Military, aerospace, and high-reliability industrial applications.

- Pros:

- Provides more accurate models compared to MIL-HDBK-217.

- Reflects the latest technologies and components.

- Cons:

- Not as widely adopted as MIL-HDBK-217.

- Complex calculations and data requirements.

6. SN 29500

- Full Name: SN 29500: Siemens Norm for Failure Rates of Electronic Components

- Origin: Siemens AG

- Purpose: Provides failure rate data and models specifically for electronic components used in Siemens products, with a focus on industrial automation and control systems.

- Applications: Industrial automation, control systems, and process instrumentation.

- Pros:

- Tailored for industrial applications, especially Siemens products.

- Regularly updated with real-world field data.

- Cons:

- Primarily focused on components used in Siemens equipment.

- Limited applicability outside of industrial automation and Siemens-specific designs.

Which One is Most Useful?

- For Military and Aerospace: MIL-HDBK-217F (legacy systems) or FIDES (modern systems).

- For Telecommunications: Telcordia SR-332 or Siemens SN 29500

- For Industrial and Commercial Electronics: IEC 61709 or Telcordia SR-332.

- For High-Reliability and Aerospace Systems: FIDES Guide or 217Plus.

All of these reliability prediction standards are supported by RAM Commander from ALD Software, making it a versatile tool for engineers across various industries

Other ALD Software Tools

Safety Commander- Safety Commander (RAM Commander Enterprise Collaboration Edition) is the only off-the-shelf software that provides fail-safe design for any System of System Safety Assessment (SoSSA) across multiple industries, including aerospace, railway, communication, and energy. With the ability to perform safety analysis integration on the level of aircraft or system-of-systems , Safety Commander sets itself apart as a unique solution in the market..

D-LCC – Advanced tool for life cycle cost calculation, total ownership cost and sensitivity cost analysis.

FavoWeb FRACAS – Web-based or cloud-based dynamic incident/failure/fault management system: FRACAS world leading.

See Also

ALD Reliability and Safety Software

ALD Reliability, Safety and Quality Services

Reliability&Safety Software Download

We've put together a selection of answers to the questions most frequently asked about FavoWeb FRACAS features and capabilities. They are arranged by topic and are updated regularly.

Overview

What is FavoWeb FRACAS software?

FavoWeb FRACAS from one viewpoint is a logistic application managing the collection of events data surrounding all aspects of a product (i.e. Production Floors, Maintenance, and Design etc). From a second viewpoint it is an analytic tool which enables the R&M engineer to get the information needed for product improvement. Joining these two approaches together closes the loop for the process known as FRACAS.

What is FRACAS?

Failure Reporting, Analysis, and Corrective Action System (FRACAS) is a closed-loop feedback path in which the user and the supplier work together to collect, record, and analyze failures of both hardware and software data sets. The user captures predetermined types of data about all problems with a particular tool or software and submits the data to that supplier. A Failure Review Board (FRB) at the supplier site analyzes the failures, taking into consideration such factors as time, money, and engineering personnel. The resulting analysis identifies corrective actions that should be implemented and verified to prevent failures from recurring.

Who are FavoWeb FRACAS users?

FavoWeb FRACAS, being a cross organization tool, is directed to several user-roles. The logistics side of collecting the data includes Technicians, Supervisors, Maintainers, Vendors, and Customers. The analysis side includes R&M Engineers, Managers, and Monitors. Each role with its unique access rights receives the relevant screens and data access.

What Environment is FavoWeb FRACAS running in?

FavoWeb FRACAS is installed on a server box running 2008, 2012 or 2016 Server OS. It uses Microsoft IIS for a Web server, and is written in ASP and .Net platform. Every interaction with the application is using Internet Explorer being a fully active Web Application.

What Database does FavoWeb FRACAS Support?

FavoWeb FRACAS supports Oracle 11g and 12c. In addition, it uses a parser for connecting to MS SQL server. The database can reside on another server defined to the application box database client.

Installation

Can FavoWeb FRACAS be installed from a Setup CD?

FavoWeb FRACAS can be installed from a CD, at least the components having to do with application files. For installing Database scheme there should be more steps to be done:

- Create a user in the database.

- Import the DMP file that came with the installation set into the new user.

- Direct the data link file to the right user.

How does FavoWeb FRACAS handle history records?

For a one time process, FavoWeb FRACAS has an Import module that use history record formats and defines a mapping template to read/import data into FavoWeb FRACAS. If the situation is reading records from another application on regular basis, FavoWeb FRACAS uses Web Services technology to get in data directly from the external data source.

What does FavoWeb need installed on the application server?

FavoWeb FRACAS requires the following to already be installed on the application server: Database Client/Server components, Excel 2010 and up installed, .NET framework 4.7. Also IIS 7.0 - 8.5 is required.

What are FavoWeb FRACAS Hardware requirements?

FavoWeb requires a minimum of: 16 GB memory, 3.3 GHz or faster 64-bit dual-core processor, 40gb hard disk, Network Card etc. As the application grows, with an increase in the number of users, Network being overloaded, the hardware will need to be adapted.

Customers/Markets

What market is FavoWeb FRACAS aimed at?

FavoWeb has an application generator at its Backend. This allows for defining forms, fields, workflow process and reports to fit the desired market. Up until today we have installations in the army covering military systems, in the Aviation industry covering design, production and maintenance phases. Also we have a customer that manufactures water purification systems, automotive, light train, electronic components, medical systems and more.

Does FavoWeb FRACAS supply a pre-defined system matching the customer's area of work?

As a part of the basic set delivery, FavoWeb delivers a start application which is a pre-defined generic application. This is a starting point for the customer after which the application is tailored to his specific semantics and business logic. FavoWeb can alternately use its experience and create a per order application answering 100% of customer requirements. This work will be done separately for a separate fee at its own price.

Who owns FavoWeb FRACAS inside the customer's organization?

This depends on the organization interrelations. As much as FavoWeb becomes a cross-organization application the responsibility goes to the IT department. This includes system administration, DB management, Helpdesk support and contact with FavoWeb FRACAS support team. When the organization is small or the tool is used only partially throughout the organization the direct "owners" are the main users - the FRACAS people in the Reliability department.

Who really needs a FRACAS application?

The closed loop process called FRACAS is the only way a company can make improvements on the product. The techniques can vary from one process to the next. The concept is the same, to collect data, analyze it and embed changes in the process. As the product goes through its life cycle the cost for implementing design changes gets higher. The earlier the flaws are found the lower the cost for improvement is. This means that it is every manufacturing company's interest to hold such a process. There are organizations that need FRACAS as part of a quality standard they need to follow or because a requirement of a government agency.

Main Features

Is FavoWeb FRACAS an application generator?

FavoWeb is really an application generator. It has an interface that defines how the user will work with the system. You can define the application title and the logo of your company to be shown on the screen. You can put a disclaimer message and even change the number of lines in a record list. All of that is defined through the Admin console within the tool.

Does FavoWeb FRACAS support multi-lingual interface?

FavoWeb supports multi-lingual user interface, by not only allowing data to be entered in other languages than English, but also the titles, the text on the buttons etc to be in the defined in these languages. More over, you can set forms in a way that in Rome an engineer can fill in fields in Italian and in the HQ in New York the report will print in English.

I already have paper Failure Forms. Can I use these formats in FavoWeb FRACAS?

FavoWeb Admin console defines the input forms in a simple intuitive way. The number of forms in a failure report and their contents are to meet the failure workflow and logic. When there is already a paper form with defined fields and options it makes the definition process much easier.

What types of fields can FavoWeb form contain?

FavoWeb FRACAS has many field types to be used in a form. The simplest is the regular field type that can hold text, number or date formats. The next type is a library field that comes in a tree-like layout, multi-select list, combo-box, or a popup select table. There are the file attachment field, signature, and the caption/title field. Also there is a field that triggers the items library. This field comes in two layouts - selection product tree and an items list layout. There are user data fields, part virtual fields and more.

Can fields become mandatory or hidden on the form?

Each field has a set of attributes defining extra characteristics. For instance, hidden, mandatory, in-window (field shows in failure list screen as a column), limit to list, locked (read only) and more.

How does FavoWeb FRACAS handle permissions?

FavoWeb has a deep access-rights/permissions mechanism. It relies on dividing the users into roles/user-groups. Every group's permissions are defined separately; this way a user logging into FavoWeb sees only what he has rights for.

What about standard user authentication methods like LDAP?

FavoWeb has three levels of user authentication configuration. The first level is controlling passwords within the tool. This is done when the application works in an independent mode with no interaction with external directory servers. The second level is logging into FavoWeb FRACAS directly but the password authentication is done through LDAP against a directory Server (i.e. Active Directory). The third level is logging into an organization application portal where the password is authenticated. Users link to FavoWeb through the portal where an RSA encrypted string is used to authorize FavoWeb FRACAS connections.

Aside of Failure Data, how does FavoWeb track Review Boards activity?

FavoWeb FRACAS has a special module for recording Review Boards activities. It tracks four levels of data: Logistic information about the board meeting (date, participants, chairperson etc.), problems/issues discussed at the meeting (problem category, associated failures, status, severity, solution goal), Corrective Actions assigned to each of the problems (including person/department responsible for the task, planned completion date, closing date etc), and progress lines for each corrective action (status date, percent progress, detail information).

Does FavoWeb FRACAS support Serial Number tracking?

FavoWeb deals with S/N in more than one level. First, as part of a failure/repair record FavoWeb adds a S/N fields for the Replaced/Repaired components. If S/N does not exist (i.e. in production processes) FavoWeb uses instead the Batch No or Work-order with a Line No. This is important for tracking field failures back to the production phase. The other level is the System S/N field. FavoWeb ties failure events to the specific system S/N it occurred in. For that FavoWeb holds a system list and gathers information for each specific system: history records, AS-BUILT SRU list, Operational Hours, Date system was installed and more. This is important for reliability calculations like MTBF and Availability algorithms.

Can I record only failure events or all types of information that I need to track like Scheduled Maintenance Events or Testing results?

FavoWeb FRACAS, being an application generator, can create forms at customer's requests. Through the Admin Console you can give it a desired label like "Testing Results" and create forms that support testing types of data. Later on, you can write special reports and calculations that fit the data collected inside.

Can FavoWeb add new form functionality according to customer requests?

FavoWeb has a built-in mechanism for adding customer-tailored functionality to a form without influencing the core-version of the application. Every field added to a form has a parameter - "Special Function ASP program" where a special ASP filename can be written. When this parameter is filled, the application puts a special button next to the field in the form, and clicking that button runs the special ASP program. This program can validate some logic between fields, can update other tables or can bring in values to the form from external data sources.

How does FavoWeb FRACAS handle a product tree? Can it use our PDM by connecting online?

FavoWeb deal with a product tree on two levels. The first one is to manage the product tree internally. FavoWeb has a special module for doing that. This module manages both an item list and the father-son hierarchy of the product. The second level is connecting online to an existing product management application with a "view mechanism". This method allows for one side to interact with and be always up to date with the product definition and for the other side to let the product be managed by the PDM people.

We have data in several formats. How can we import it into FavoWeb FRACAS?

FavoWeb has an import utility for these tasks. Data is imported into FavoWeb via Excel files, many of them having the same field structure. The Import module simplifies the ongoing running of the FavoWeb system. Instead of manually entering data, such as failure reports (each and every failure is entered separately), by the user, the data-entering function can be automated, by importing the data in Excel files that were prepared beforehand. Typically, these files contain data relating to failures and their repairs, clocks, items and libraries.

Analysis/Output reports

Is there a way in FavoWeb FRACAS to create our own simple slice and dice reports (i.e. Top 5 failing parts with priority HIGH)?

FavoWeb has two types of Ad-Hoc report generators for this reason. The user can use these reports to create "on the fly" reports by selecting columns, sort fields, two levels of Group-By fields and a criteria/filter textbox to select report population. One report is called a failure list report used to display a list of selected failure records in a grid type layout. The second report is to create "Top XX" type of reports displaying a table and a graph. Both outputs can be in either Excel or Html formats. A pre-run report parameters can be saved for a future reuse.

What is the MTBF calculation and does FavoWeb use it?

MTBF stands for Mean Time Between Failures, and is the most popular parameter to tell a product reliability. This parameter is used for example in a product improvement process or to decide the inventory level a system needs. FavoWeb calculates this parameter from failures history taking into account only relevant events. For the time component FavoWeb uses the operational system hours collected or as alternative the calendar time for the period required. This algorithm uses confidence level method for setting borders and implements modern statistical techniques in the calculation.

What other R&M parameters does FavoWeb FRACAS use for analysis?

FavoWeb uses many different methods of calculation to help manage the product improvement process. MTTR (mean time to repair) tells the engineer the net average repair time for each task. On the other hand the Mean Logistics Time takes into consideration not only the repair time but all the time frame between the time a failure is opened and the time the repair is closed. Availability is an important calculation that gives us an idea what percentage of the time the system is active out of the whole system activity time.

Does FavoWeb FRACAS analyzes Warranty issues and how?

FavoWeb uses Warranty Analysis is to make recommendations for product profit reduction. This is done both for repairable and non-repairable data and is based on several approaches. FavoWeb uses Weibull Analysis, Reliability Growth Analysis, Mean Cumulative Function approach and more. The outputs of Warranty Analysis are:

- Recommendation for warranty periods.

- Recommendations for spare parts amount.

- Recommendations for product reliability improvement.

What is the Weibull Analysis and how is it implemented in FavoWeb FRACAS?

Weibull distributions are often used to model the time until a given technical device fails. Manufacturers will often supply the shape and scale parameters for the lifetime distribution of a particular device. The aim of FavoWeb Weibull Analysis is to handle statistical failure data and to define statistical distribution parameters, confidence intervals, etc. You can use completed data, censored, interval and grouped data, to select methods of analysis (maximum likelihood estimation or regression) and amount of estimated parameters (only shape and scale or also location).

Does FavoWeb FRACAS support Reliability Growth calculation and how?

FavoWeb uses Reliability Growth Analysis to handle statistical data, which essentially is dependent on time-variable failure rate. Possible scenario of entering failure times would be re-designing of a product during testing, after each single failure.

How does FavoWeb FRACAS measure the performance of the product improvement process itself?

FavoWeb records many types of information that describes the Integrated Product Teams and Failure Review Boards work. The information collected includes investigation goal, number of Corrective Actions needed to close the problem, actual board close date against planed end date, effectiveness and more which gives FavoWeb more than enough data to calculate board efficiency.